ABOUT

About Paramount

The company has always been to "high-quality products", "punctual delivery", "good reputation service" as the basic criteria.

Paramount Steel Detailer Co., LTD.

Paramount Steel Detailer Co., LTD. was established in 2004 and currently has 22 full-time design personnel, including 2 technical directors and 5 technical project leaders. The average experience of the design personnel is over 8 years, with 11 of them having over 10 years of experience. The technical directors have over 15 years of experience in deepening detailed drawings both domestically and internationally, and are capable of completing technical service work for various types of steel structures in various countries. From the start of project bidding to the end of project construction, the technical service work covers the entire life cycle...

Company establishment

Full-time designer

Tekla (10 sets with permanent copyright, 7 sets for lease)

Autocad genuine software

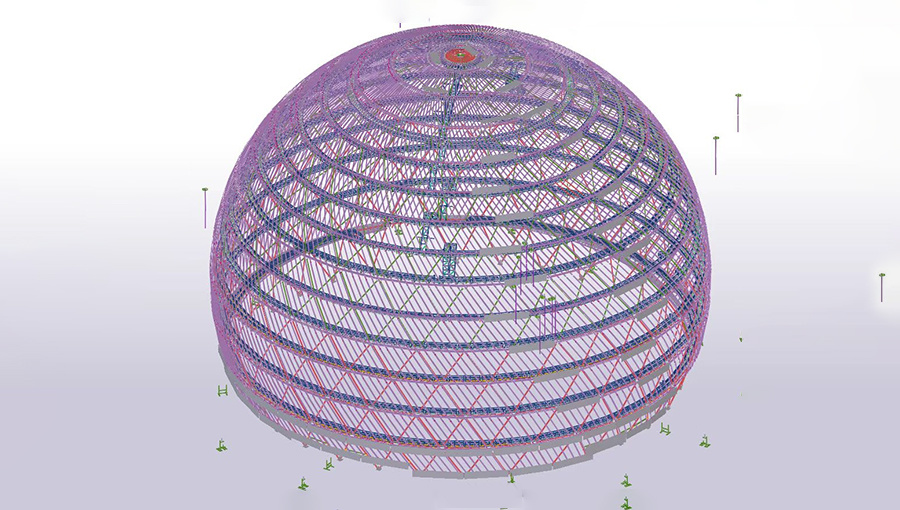

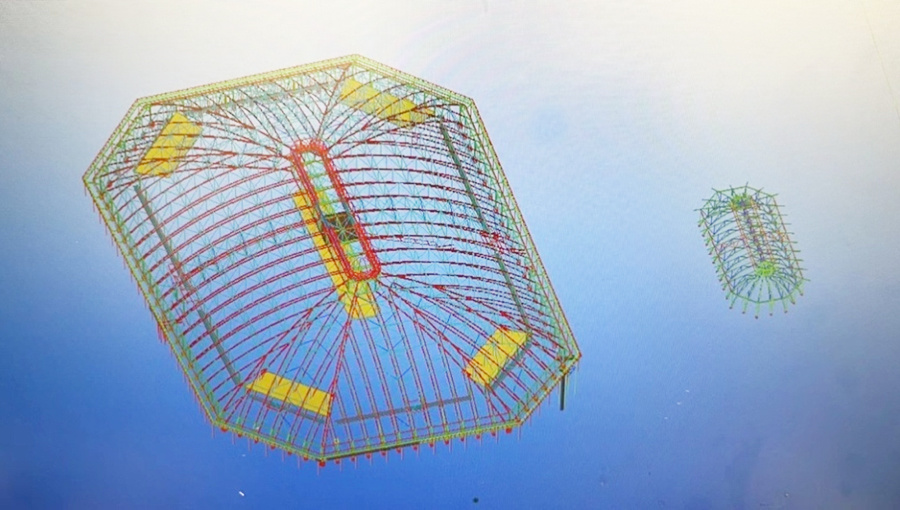

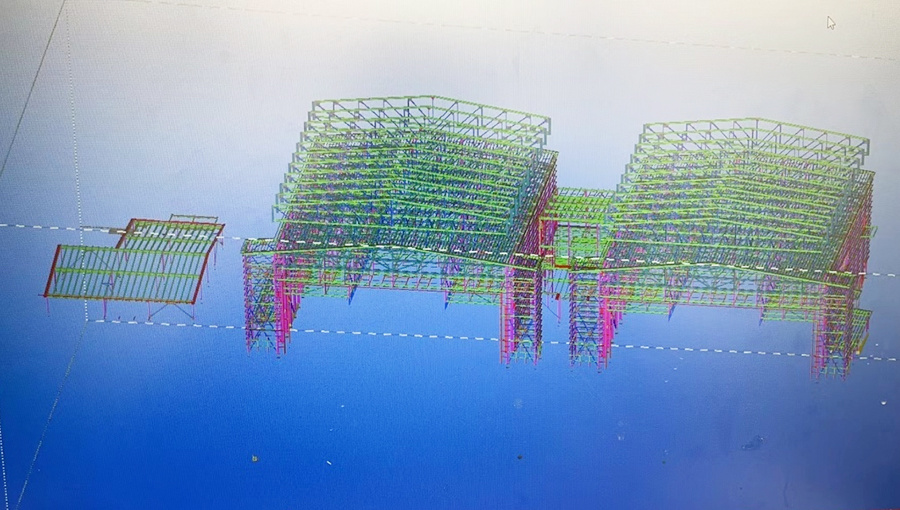

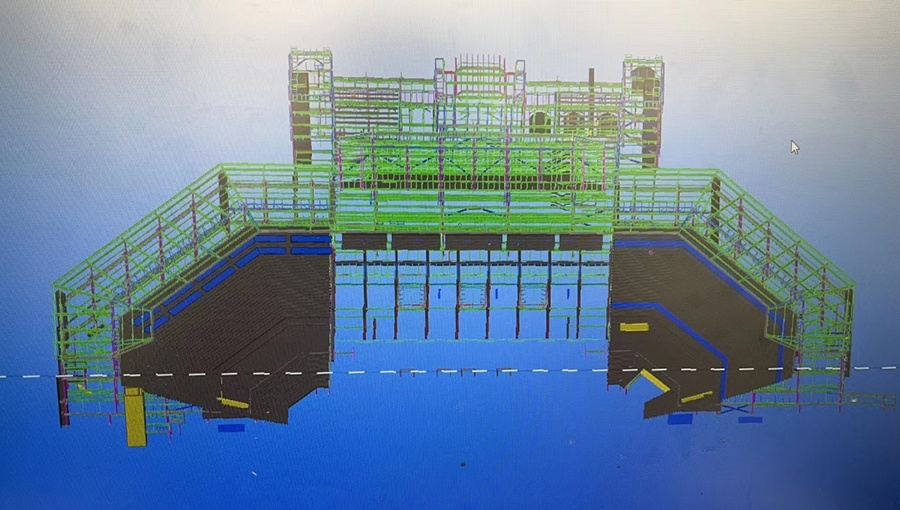

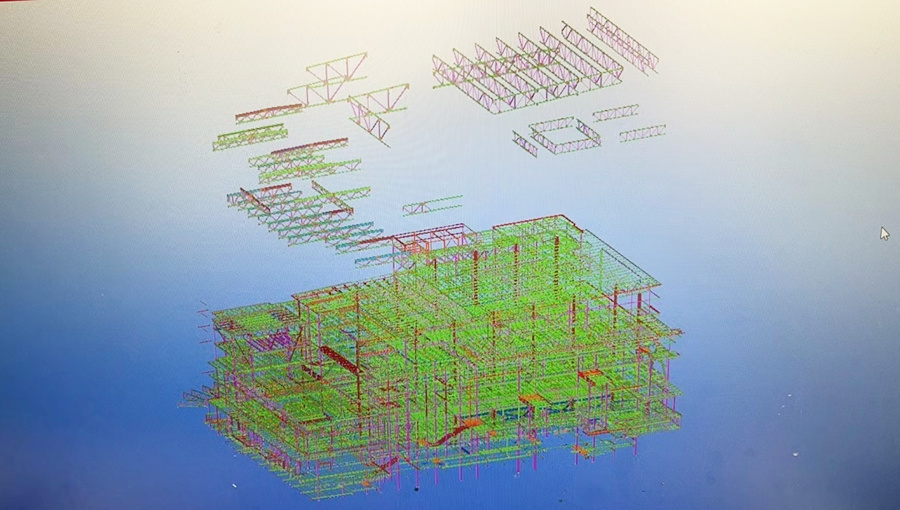

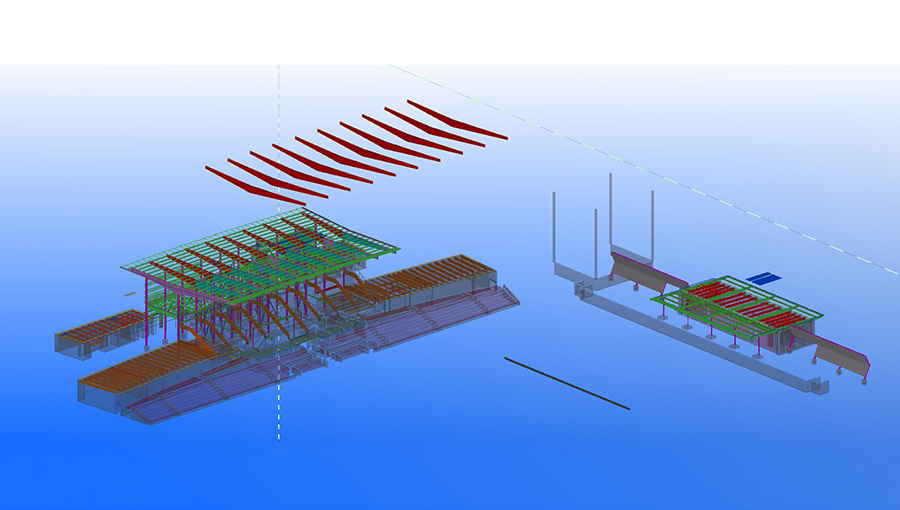

PROJECTS

Engineering Case

Quality for the survival of the fundamental, attentive service, sincere for you

NEWS

News

Follow us and get more real-time information.

How to choose the right steel structure processing factory for project collaboration?

In the modern construction industry, the application of steel structures is becoming increasingly widespread. Whether it is skyscrapers, bridges, or various industrial facilities, steel structures have become the preferred material for many construction projects due to their high strength and durability. Therefore, finding a suitable steel processing factory for collaboration is an important issue that every project manager and construction team must face. Today, let's talk about how to choose the right steel processing factory.

2025-01-10

Nanotechnology in large steel structure anti-corrosion

Large steel structures are an important component of extensive infrastructure. Bridges, power plants, oil and water pipelines, oil and gas storage tanks, large production facilities, ships, offshore structures, towers, and many large buildings extensively use steel structures. Although the carbon steel used has good mechanical properties and reasonable prices compared to some low-alloy steels, they face serious electrochemical corrosion issues. Due to their large usage and long lifespan requirements, the necessary anti-corrosion measures are also unique. Among various corrosion control methods, different surface treatments and the application of anti-corrosion coatings are primarily chosen to protect large steel structures. So far, it can be said that in most cases, the protective effects are still far from ideal, mainly due to the lifespan issues of the covering layer caused by chemical and mechanical failures. Therefore, developing high-performance, long-lasting surface modification technologies and anti-corrosion products that meet environmental protection requirements under new conditions is an important task. Solving such problems relies on high technology, new ideas, and their adoption.

2025-01-10

2025-01-10

How to choose the right steel structure processing factory for project collaboration?

In the modern construction industry, the application of steel structures is becoming increasingly widespread. Whether it is skyscrapers, bridges, or various industrial facilities, steel structures have become the preferred material for many construction projects due to their high strength and durability. Therefore, finding a suitable steel processing factory for collaboration is an important issue that every project manager and construction team must face. Today, let's talk about how to choose the right steel processing factory.

2025-01-10

Nanotechnology in large steel structure anti-corrosion

Large steel structures are an important component of extensive infrastructure. Bridges, power plants, oil and water pipelines, oil and gas storage tanks, large production facilities, ships, offshore structures, towers, and many large buildings extensively use steel structures. Although the carbon steel used has good mechanical properties and reasonable prices compared to some low-alloy steels, they face serious electrochemical corrosion issues. Due to their large usage and long lifespan requirements, the necessary anti-corrosion measures are also unique. Among various corrosion control methods, different surface treatments and the application of anti-corrosion coatings are primarily chosen to protect large steel structures. So far, it can be said that in most cases, the protective effects are still far from ideal, mainly due to the lifespan issues of the covering layer caused by chemical and mechanical failures. Therefore, developing high-performance, long-lasting surface modification technologies and anti-corrosion products that meet environmental protection requirements under new conditions is an important task. Solving such problems relies on high technology, new ideas, and their adoption.